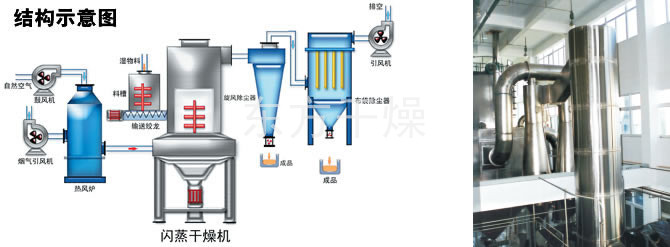

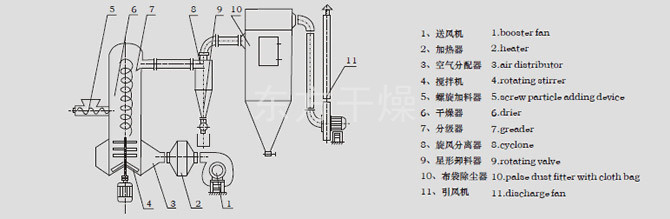

Working principle

Tangent into the bottom of the hot air dryer, a powerful rotating wind field is formed in the driving of the stirrer. Paste material from the screw feeder into the dryer at high speed stirring blade intense action, the material by the impact, the role of friction and shearing force is dispersed, the bulk materials will soon be smashed full contact with the hot air, heat ,dry. The dehydrated material dry with hot air rising, grade large ring particle retention, small particles from the dryer exhaust outside the center of the ring by the cyclone and dust recycling, not dry or bulk materials Shuaixiang wall by centrifugal force again fall to the bottom was crushed dried.

Features

◎ cyclone, fluidized, spouted and smashing step technologies combine.

◎ equipment is compact, small size, high efficiency, continuous production, to achieve a "small equipment, large-scale production."

◎ drying intensity, low energy consumption, high thermal efficiency.

◎ residence time is short, good product quality, can be used for drying heat sensitive materials.

◎ negative or slightly negative pressure operation, tightness, high efficiency, eliminate environmental pollution.

Adapt materials

Organic compounds: atrazine (pesticides), cadmium laurate, benzoic acid, germicide,

Sodium oxalate, cellulose acetate, and other organic pigments.

Dyes: anthraquinone, black iron oxide, indigo pigments, butyric acid, zinc sulfide, various coupling

Azo dyes intermediates.

Inorganic materials: borax, calcium carbonate, calcium hydroxide, copper sulfate, iron oxide, barium carbonate, antimony trioxide,

Various metal hydroxides, all kinds of heavy metallic salt, synthetic cryolite and the like.

Food: soy protein, gelatinized starch, lees, wheat, wheat starch and the like.

Technical Specifications

| Model | XSG-2 | XSG-4 | XSG-6 | XSG-8 | XSG-10 | XSG-12 | XSG-16 | XSG-20 |

| Host Nei Jing mm | 200 | 400 | 600 | 800 | 1000 | 1200 | 1600 | 2000 |

| Wind M3/h | 350-500 | 1150-2000 | 2450-4500 | 4450-7550 | 7000-12500 | 10000-20000 | 18000-36000 | 28200-56500 |

| Evaporation of water kg/h | 12-17 | 40-70 | 80-150 | 150-250 | 230-4250 | 300-600 | 600-1000 | 1000-1500 |

| Maximum Capacity kw | 10 | 20 | 40 | 65 | 85 | 105 | 150 | 230 |

| Maximum height m | 4.0 | 4.8 | 5.8 | 6.5 | 7.1 | 7.8 | 8.8 | 10.1 |

| Covers m2 | 15 | 20 | 28 | 35 | 40 | 52 | 80 | 150 |

Note: 1 is the amount of water evaporation into the air temperature was 80oC 1, the air temperature was 80oC evaporation of water per hour,

2. In addition to the above model for outside users to make a special design,

3. The above standard package installed capacity, according to the material can significantly reduce support different power.

Material handling and characteristics (type 6 flash as a benchmark)

| Material name | Stearate | Aluminum hydroxide | Zinc carbonate | Monosultap | TMTD | DSD acid | Red iron oxide | Carbon dioxide | Cuprous chloride | Silica |

| Inlet air temperatureoC | 150 | 180 | 150 | 120 | 140 | 150 | 200 | 180 | 200 | 280 |

| First moisture content% | 80 | 55 | 80 | 30 | 65 | 60 | 60 | 45 | 30 | 85 |

| Final moisture content% | 0.5 | 1.5 | 1.0 | 1.0 | 0.5 | 0.5 | 0.5 | 1.0 | 3.0 | 5.0 |

| The actual drying capacitykg/h | 140-160 | 250-280 | 130-170 | 80-110 | 80-120 | 80-120 | 300-350 | 280-320 | 290-310 | 250-300 |

| Material name | Accelerant | Oil-soluble ink | Metabolic acidosis MnZn | Phthalocyanine blue | Calcium citrate | Ultrafine | Mud additives | Isocyanuric acid sodium dioxide | Three oxygen iso cyanuric acid sodium |

| Inlet air temperatureoC | 150 | 150 | 120 | 150 | 140 | 160 | 200 | 180 | 150 |

| First moisture content% | 60 | 45 | 30 | 55 | 40 | 70 | 75 | 25 | 30 |

| Final moisture content% | 0.5 | 2.0 | 1.0 | 1.0 | 1.0 | 1.5 | 5.0 | 0.2-2 | 1.0 |

| The actual drying capacitykg/h | 80-110 | 350-380 | 120-150 | 160-180 | 300-350 | 430-470 | 290-310 | 80-120 | 90-150 |