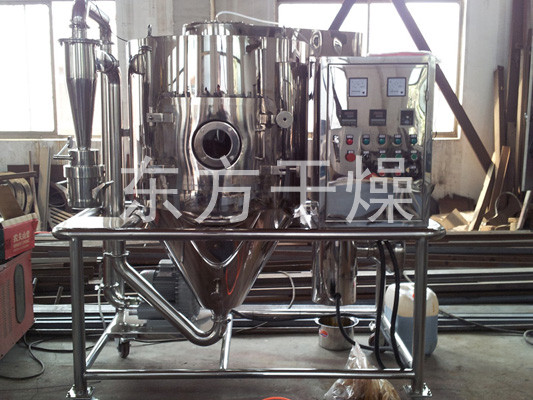

Product description

Spray drying is a process liquid process shaping and drying industry is the most widely used. Ideal for generating powdery, granular solid product from the solution, emulsions, suspensions and pasty liquid feedstock. Thus, when the finished product particle size distribution, residual moisture content, bulk density and particle shape must meet the precision standard, the spray drying is an ideal process.

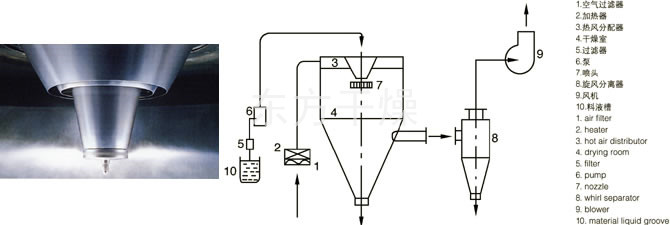

Working principle

Heated air through a filter and into the top of the drier air distributor, the hot air was uniformly into the drying room in the spiral. Passing through the top of the tower high-speed centrifugal atomizer (rotary) sprayed into the extremely fine mist liquid beads in contact with the hot air stream and in a very short period of time can be dried into a finished product. Finished continuously from the bottom of the drying tower and cyclone exhaust gases vented by the fan.

Features

◎ drying speed, greatly increasing the surface area of the material after the liquid is atomized in a stream of hot air, it can instantly evaporate 95% -98% of water to complete the drying time of just a few seconds, especially suitable for drying heat sensitive materials.

◎ product has a good uniformity, mobility and solubility, high purity and good quality.

◎ production process is simplified, easy to operate controls. For moisture content of 40-60% (for special materials, up to 90%) of the liquid can be dried into a powder product, after drying without crushing and screening to reduce the production processes, improve product purity. For the size, bulk density, moisture, within a certain range can be adjusted by changing the operating conditions, the control and management is very convenient.

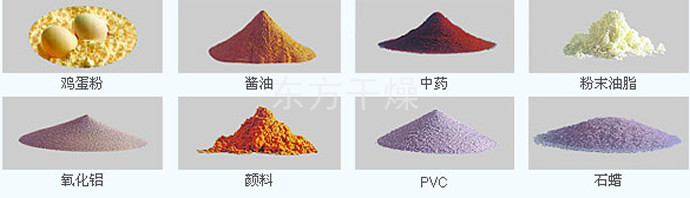

Adapt materials

Chemical industry: sodium fluoride (potassium), basic dye pigments, dyes intermediates, fertilizer, formic silicic acid, catalyst, sulfuric acid agent, amino acid, white carbon black.

Plastic resin: AB, ABS latex, urea-formaldehyde resins, phenolic resins, dense glue (urea) formaldehyde resins, polyethylene, polyvinyl chloride and the like.

Food industry: fat-rich milk, armpit protein, cocoa milk powder, substitute milk, hunting blood meal, egg white (yellow) and the like.

Food and plants: oats, chicken juice, coffee, instant tea, seasoning meat, protein, soybean, peanut protein, hydrolyzate and so forth.

Sugar: corn syrup, corn starch, glucose, pectin, malt sugar, potassium sorbate.

Ceramics: alumina, ceramic tile material, magnesium oxide, talc and the like.

Technical Specifications

|

Model Item / Parameter |

5 | 25 | 50 | 150 | 200-2000 |

| Inlet temperature | 140-350 Automation | ||||

| Outlet temperature | 80-90 | ||||

| The maximum amount of moisture evaporation(kg/h) | 5 | 25 | 50 | 150 | 200-2000 |

| Centrifugal spray head drive form | Compressed air drive | Mechanical transmission | |||

| Maximum speed(r.p.m) | 25000 | 18000 | 18000 | 15000 | 8000-15000 |

| Spray disk diameter(mm) | 50 | 120 | 120 | 150 | 180-240 |

| Heat | Electricity | Steam + electricity | Steam + electricity, fuel, gas, stove | ||

| Electric heating maximum power(kw) | 9 | 36 | 72 | 99 | |

| Dimensions (length × width × height)(m) | 1.8×0.93×2.2 | 3×2.7×4.26 | 3.5×3.5×4.8 | 5.5×4×7 | Determined according to the actual situation |

| Dry recovery(%) | ≥95 | ||||

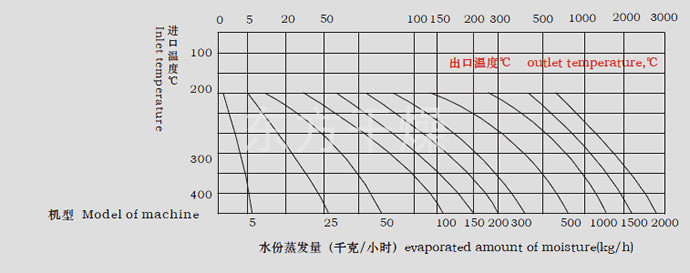

Note: The characteristics and thermal evaporation of water and the material inlet, outlet temperature-dependent. When the outlet temperature was 90 o C, its water evaporation curve shown above (for the selection of reference), with product updates, relevant parameters to change without prior notice.

Ordering Information

◎ name was material, the physical properties: Solid content (or water content), viscosity, surface tension, PH value incl.

After ◎ dried powder capacity, allow the residual water content, particle size, the maximum temperature allowed.

◎ production, opening times of the day.

◎ available energy: vapor pressure for the amount of capacity available for coal, oil, gas.

◎ control requirements: inlet and outlet temperatures need to be controlled.

◎ powder collecting requirements: whether you want to install the trap bag, environmental requirements for exhaust emissions.

◎ other special requirements.

Technical Specifications

| Size | A | B | C | D | E1 | E2 | F | G | H | I |

| LPG-25 | 1290 | 3410 | 4260 | 1800 | 1200 | 1200 | 1000 | 1700 | 1300 | 1550 |

| LPG-50 | 1730 | 4245 | 5100 | 2133 | 1640 | 1640 | 1250 | 1750 | 1800 | 1600 |

| LPG-100 | 2500 | 5300 | 6000 | 2560 | 2100 | 2100 | 1750 | 1930 | 2600 | 1780 |

| LPG-150 | 2800 | 6000 | 7000 | 2860 | 2180 | 2180 | 1970 | 2080 | 3050 | 1960 |

| LPG-200 | 2800 | 6600 | 7300 | 3200 | 2300 | 2300 | 2210 | 2250 | 3050 | 2100 |

| LPG-300 | 2800 | 8000 | 8700 | 3700 | 2800 | 2800 | 2520 | 2400 | 3040 | 2250 |