Product description

DWC dehydration dryer is in the traditional net belt dryer, based on research and development of special-purpose equipment, highly targeted, practical, high energy efficiency. Widely used in various regional and seasonal vegetables, fruit dehydration dry. Such as: garlic, pumpkin, konjac, white radish, yam, bamboo shoots. When we as users, production equipment, according to the desired characteristics of the dried product, the user process requirements, combined with decades of accumulated experience, designed for users of the most applicable. Best quality vegetables drying equipment.

Working principle

Vegetable dehydration dryer respectively, feeder, drying beds, heat and humidity and fans and other major components. Dryer operation. Cold air through the heat exchanger for heating, using scientific and reasonable cycle mode, the hot air flow through a uniform heat and mass transfer through the bed surface of the material to be dried, the body of the unit under the action of heat airflow circulating hot air circulating fan Finally, low temperature and high humidity of the air is discharged, smoothly and efficiently complete the entire drying process.

Features

Drying area, air pressure, air flow, drying temperature belt running speed can be adjusted. To adapt to the characteristics and quality requirements of vegetables.

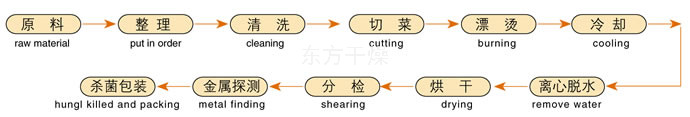

ccording to the characteristics of vegetables, using a different process and add supporting the necessary auxiliary equipment.

Adapt materials

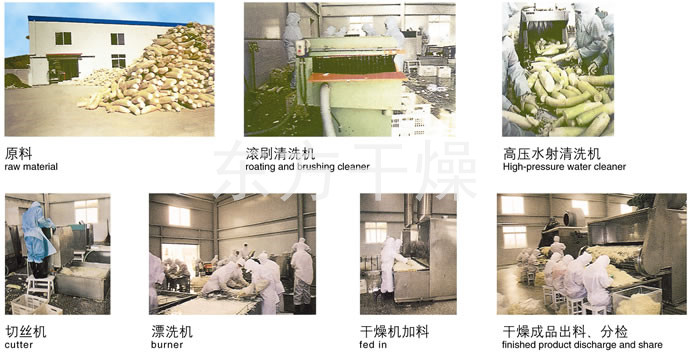

To meet the root, dried stem, leaf strips, blocks, plates, large granular and other vegetable materials and large-volume continuous production, and can maximize the retention of nutrients and product color.

Typical dry materials are: garlic, pumpkin, carrots, konjac, yam, bamboo shoots, horseradish, onion, apple and so on.

Technical Specifications

| Model |

DWC1.6-Ⅰ (Charging station) |

DWC1.6-Ⅱ (Intermediate stage) |

DWC1.6-Ⅲ (Discharge units) |

DWC2-Ⅰ (Charging station) |

DWC2-Ⅱ (Intermediate stage) |

DWC2-Ⅲ (Discharge units) |

| Broadband network(m) | 1.6 | 1.6 | 1.6 | 2 | 2 | 2 |

| Long drying section(m) | 10 | 10 | 8 | 10 | 10 | 8 |

| Shop material thickness(mm) | ≤100 | ≤100 | ≤100 | ≤100 | ≤100 | ≤100 |

| Operating temperature(oC) | 50-150 | 50-150 | 50-150 | 50-150 | 50-150 | 50-150 |

| Heat transfer area(m2) | 525 | 398 | 262.5 | 656 | 497 | 327.5 |

| Steam pressure(MPa) | 0.2-0.8 | 0.2-0.8 | 0.2-0.8 | 0.2-0.8 | 0.2-0.8 | 0.2-0.8 |

| Steam drying time (h) | 0.2-1.2 | 0.2-1.2 | 0.2-1.2 | 0.2-1.2 | 0.2-1.2 | 0.2-1.2 |

| Transmission power(kw) | 0.75 | 0.75 | 0.75 | 0.75 | 0.75 | 0.75 |

| Dimensions(m) | 12×1.81×1.9 | 12×1.81×1.9 | 12×1.81×1.9 | 12×2.4×1.92 | 12×2.4×1.92 | 10×2.4×1.92 |