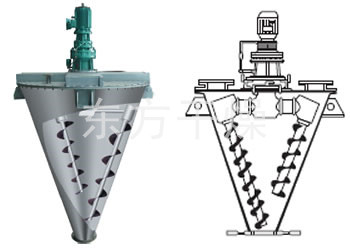

Product description

By the spiral of the public, so that the material to produce a composite rotation motion in the cone, mainly produce four forms of exercise:

1. spiral revolution along the wall, so that the material along the awl circular motion;

2. The spiral rotation so that the material from the bottom edge of the cone spiral;

3. The public spiral, complex rotation movement of a portion of the material to be absorbed into the centrifugal forces as well as by the spiral rotation of spiral cylindrical surface so that part of the material to the inner cylindrical surface helix radial discharge cone;

4. The rise of the material by its own gravity fall. Four kinds of movement in the mixer convection, shearing, diffusion, so as to achieve rapid and uniform mixing purposes.

Features

◎ can be installed knife, spray atomization assembly, to meet special requirements.

◎ outlet valve with manual, pneumatic in two ways.

◎ Special materials can increase the motor power (heavier type).

Applications

Used in chemical, pharmaceuticals, pesticides, dyes, petroleum, metallurgy, building materials and other powder and powder (solid - solid), powder and liquid (solid - liquid), liquid and the liquid (liquid - liquid) were mixed and reacted, dried ,cool down.

Technical Specifications

| Model | Unit | DSH0.3 | DSH0.5 | DSH1 | DSH2 | DSH4 | DSH6 | DSH10 |

| Full volume | (m3) | 0.3 | 0.5 | 1 | 2 | 4 | 6 | 10 |

| Load factor | 0.4-0.6 | |||||||

| Mixed material size | (um)40-3000 | |||||||

| Operating Conditions | Temperature, pressure, dust seal | |||||||

| Each output | (kg) | 180 | 300 | 600 | 1200 | 2400 | 3600 | 6000 |

| Power | (kw) | 2.2 | 2.2 | 5.5 | 5.5 | 11 | 20.7 | 30.7 |

| Mixing time | (min)4-10(Special materials are determined by test) | |||||||

| Total Weight | (kg) | 500 | 1000 | 1200 | 1500 | 2800 | 3500 | 4500 |